Reakt Turbine

The LPS Reakt turbine is a flexible, efficient, easy-to-install “neo-Kaplan” unit for new sites or environmentally friendly upgrades.

FLOW: 10-500 CFS | HEAD: 10-50 FT.

Robust design

The Reakt turbine uses fixed blades, and when appropriate a variable-speed drive to provide similar performance to a traditional Kaplan but with far fewer moving parts. The family of Reakt turbines includes options for fixed or adjustable wicket gates, horizontal and vertical orientations, and a range of four sizes. Initially designed for remote applications where maintenance poses huge challenges, the Reakt line has been conceived for bulletproof reliability in extreme conditions.

Intelligent operation

A Reakt turbine can be easily upgraded from a standardized suite of components to match the best relationship of price and value at a given site. The integral control system provides operations intelligence and prognostic/health monitoring to a remote dashboard and allows the turbine to be remotely upgraded post-commissioning.

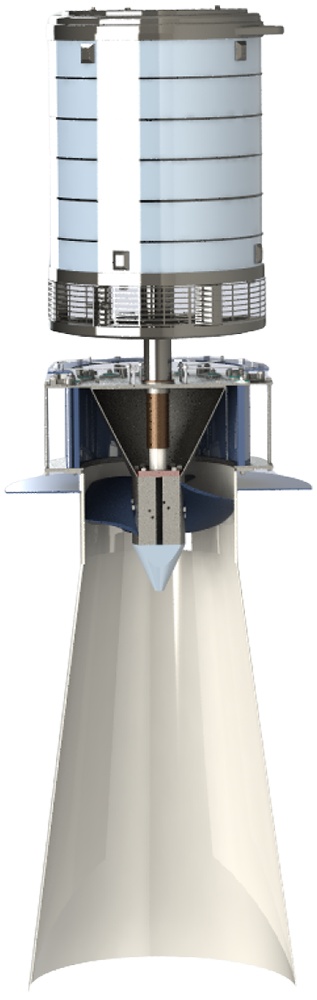

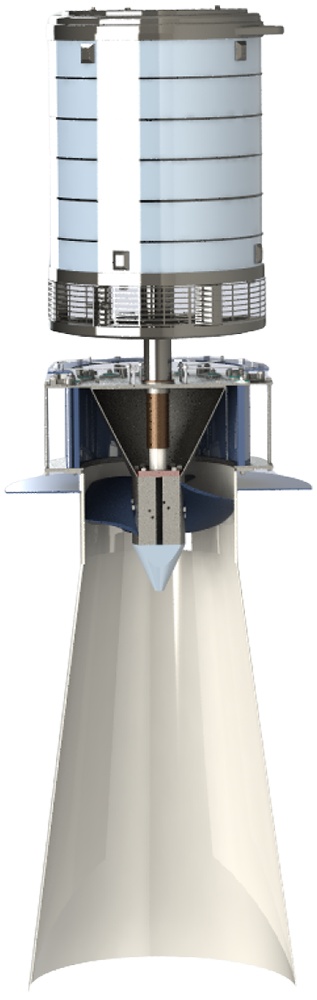

Reakt technical features

Scalable Generator

Allows easy expansion

Direct Drive

Eliminate efficiency loss

Intelligent Operation

Sensor monitor performance and system health

Wicket Gate & Bearing Assembly

Maximizes reliability while lowering maintenance

Reakt Runner

Site-optimized blades at a fraction of the traditional cost

SCALABLE GENERATOR

The Reakt system’s modular permanent magnet genset design allows for simple, inexpensive sizing of the unit’s rated capacity for site operating conditions.

DIRECT DRIVE

All Reakt systems are direct-drive. A gearbox is a major point of failure in traditional Kaplan-style systems. In addition, gearing detracts from system efficiency and adds cost.

INTELLIGENT OPERATION

Onboard sensors monitor performance for system health and ongoing optimization. When the variable-speed generator is running at full load, it can cut over to synchronous operation. This optimizes efficiency and adds spinning reserve capability, which adds value to utility plants and avails independent operators of additional economics for providing ancillary services.

WICKET GATE AND BEARING ASSEMBLY

The integrated wicket gate, shift ring, and bearing assembly maximize reliability while lowering maintenance needs. Modular integrated bearing holders accommodate standard bearings of various types to afford the user flexibility across different applications.

REAKT RUNNER

The fixed blade runner and LPS’s flexHybrid(TM) blade manufacturing technology allow “off the rack” blade customization at a fraction of the traditional cost for one-off machined blades.

Robust design

The Reakt turbine uses fixed blades, and when appropriate a variable-speed drive to provide similar performance to a traditional Kaplan with but with far fewer moving parts. The family of Reakt turbines include options for fixed or adjustable wicket gates, horizontal and vertical orientations and a range of four sizes. Initially designed for remote applications where maintenance poses huge challenges, the Reakt line has been conceived for bulletproof reliability in extreme conditions.

Intelligent operation

A Reakt turbine can be easily upgraded from a standardized suite of components to match the best relationship of price and value at a given site. The integral control system provides operations intelligence and prognostic/health monitoring to a remote dashboard, and allows the turbine to be remotely upgraded post-commissioning.

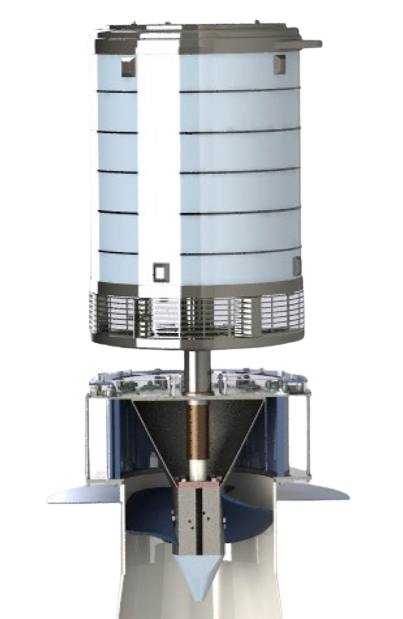

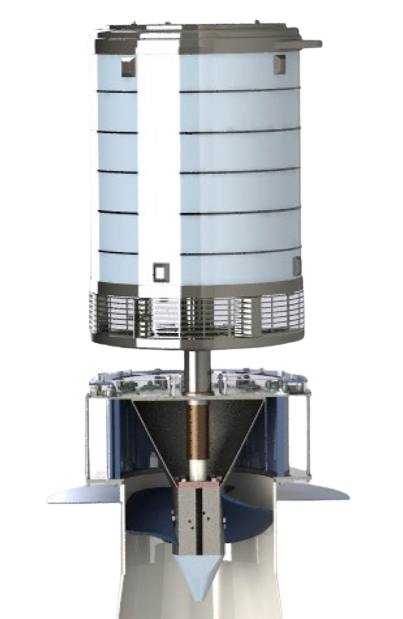

Reakt technical features

Scalable Generator

Allows easy expansion

Direct Drive

Eliminate efficiency loss

Intelligent Operation

Sensor monitor performance and system health

Wicket Gate & Bearing Assembly

Maximizes reliability while lowering maintenance

Reakt Runner

Site-optimized blades at a fraction of the traditional cost

SCALABLE GENERATOR

The Reakt system’s modular permanent magnet genset design allows for simple, inexpensive sizing of the unit’s rated capacity for site operating conditions.

DIRECT DRIVE

All Reakt systems are direct-drive. A gearbox is a major point of failure in traditional Kaplan-style systems. In addition, gearing detracts from system efficiency and adds cost.

INTELLIGENT OPERATION

Onboard sensors monitor performance for system health and ongoing optimization. When the variable-speed generator is running at full load, it can cut over to synchronous operation. This optimizes efficiency and adds spinning reserve capability, which adds value to utility plants and avails independent operators of additional economics for providing ancillary services.

WICKET GATE AND BEARING ASSEMBLY

The integrated wicket gate, shift ring and bearing assembly maximizes reliability while lowering maintenance needs. Modular integrated bearing holders accommodate standard bearings of various types to afford the user flexibility across different applications.

REAKT RUNNER

The fixed blade runner and LPS’s flexHybrid(TM) blade manufacturing technology allows “off the rack” blade customization at a fraction of the traditional cost for one-off machined blades.

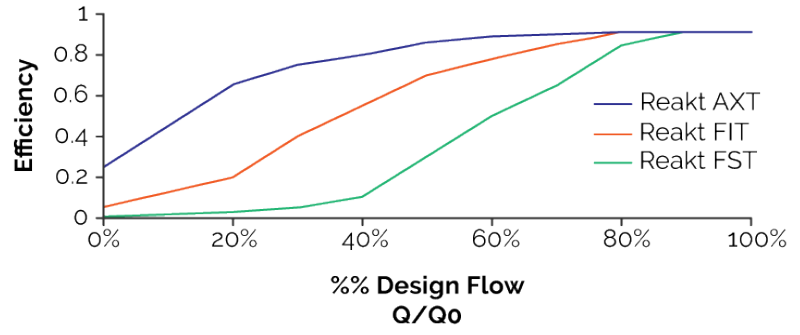

Reakt characteristic curves

AXT: dual regulation (RPM/flow)

FIT: single regulation (RPM only)

FST: unregulated: low costperformance at design flow

Reakt technical features

Model | Power (kW) | Flow (cfs.) | Head (ft.) | Runner OD (in.) |

|---|---|---|---|---|

REAKT 18 | 15-175 | 15-50 | 10-50 | 18 |

REAKT 32 | 50-400 | 51-100 | 10-50 | 32 |

REAKT 40 | 75-650 | 101-200 | 10-50 | 40 |

REAKT 52 | 150-1,000 | 201-500 | 10-50 | 52 |